UV Curing 3D Prints with UV LED Lamp and UV Crosslinker

3D Printing

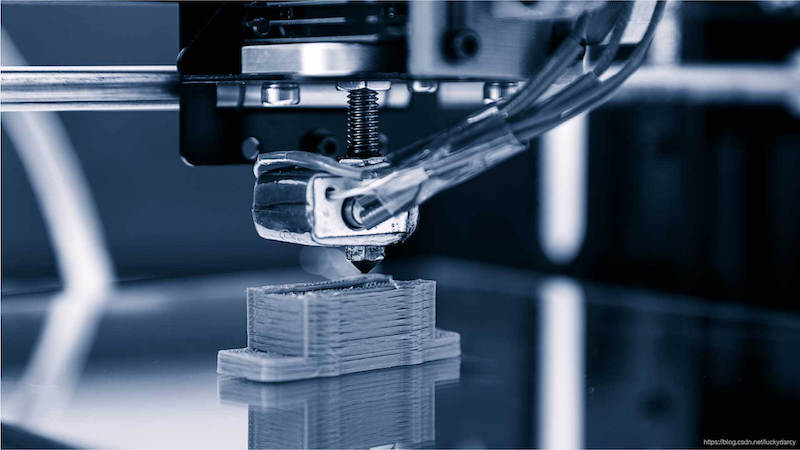

The 3D printing industry is rapidly growing. A 3D printer can be used to replicate any figure of any size with high accuracy.

There are mainly four 3D printing methods: fused deposition modelling (FDM), stereolithography (SLA), carbon CLIP technology (CLIP stands for continuous liquid interface production), and selective laser sintering (SLS). Depending on the type of compound used, the type of drying or curing will be different. From the mentioned techniques, the SLA and CLIP are the ones where photosensitive resins are employed. Generally, lasers or UV-LED lamps are used. Lasers can be used for all materials, while UV-LED lamps are applied for resins, gels, and special polymers.

Benefits of 3D Printing with UV Curing

For 3D printing with liquid resin, the curing process is essential for achieving strong and durable 3D prints. Curing involves exposing the 3D prints to 365nm longwave UV light, which causes the liquid resin to harden and solidify. This post-processing step is critical for ensuring that your 3D prints are fully cured and have the desired properties, such as strength, resilience, and durability.

UV curing is an extension of what happens during the 3D printing process – polymerization. UV curing can strengthen 3D print, increase stability and resilience, and minimize shrinkage. Polymerization is the process of putting light to photosensitive resin, which initiates a reaction that causes different molecules to bond together, creating polymer chains, and resulting in a solid print.

UV Curing Lamps Used in 3D Printing

The UV curing lamp is a device used to cure or harden resin in a 3D printing process. The UV lamp emits UV light, which triggers the photochemical reaction that solidifies the liquid resin into a solid form.

XEPU Scientific manufactures a range of UV devices (from high-intensity UV LED lamps to UV Crosslinkers) that can be used for UV curing in the 3D printing.

The UV curing time depends on the resin and the print, as well as the power and intensity of your UV curing lamp or UV crosslinker. Generally, the higher the power, the shorter the curing time. In an experiment carried out by Tsinghua University, after printing single-layer LC ink, the sample was crosslinked by 365 nm UV light at a distance of 12 cm for 40 minutes.

UV LED Lamp for UV Curing 3D Prints

UV LED Lamp XEPU-1605 is equipped with five 365nm high-quality UV LEDs, providing steady and intense UV illumination for fast UV curing. UV LED Lamp XEPU-1605 is designed for both handheld and stationary operation. It can be attached to a stand for hands-free operation and longtime curing. UV LED Lamp XEPU-1605 is an ideal tool if you want a simple but powerful UV curing lamp.

Figure below: UV Curing LED Lamp XEPU-1605, designed for easy curing of 3D prints

UV Crosslinker for UV Curing 3D Prints

UV Crosslinker XEPU-1208L is an intelligent, programmable, versatile UV curing instrument. UV Crosslinker XEPU-1208L allows the operator to set UV curing time and energy, offering precise control over different UV curing cycles. XEPU-1208L is equipped with six 8 Watt 365nm UV tubes. The large UV exposure chamber allows simultaneous curing of multiple 3D prints, increasing curing efficiency. UV Crosslinker XEPU-1208L is an excellent choice if you want precise control and faster curing.

Figure below: UV Crosslinker XEPU-1208L, excellent for intelligent UV curing